This high-precision CNC-machined part exemplifies our client’s commitment to excellence in the aerospace and medical sectors. Designed with intricate detailing and crafted from durable materials, this component is engineered to meet stringent standards for both reliability and performance in critical applications.

High-Performance Rotational Component

Engineered for seamless integration in demanding environments, this rotational CNC component showcases exceptional precision and durability. Ideal for applications that require both lightweight design and structural strength, it is tailored for the exacting standards of the medical and aerospace industries.

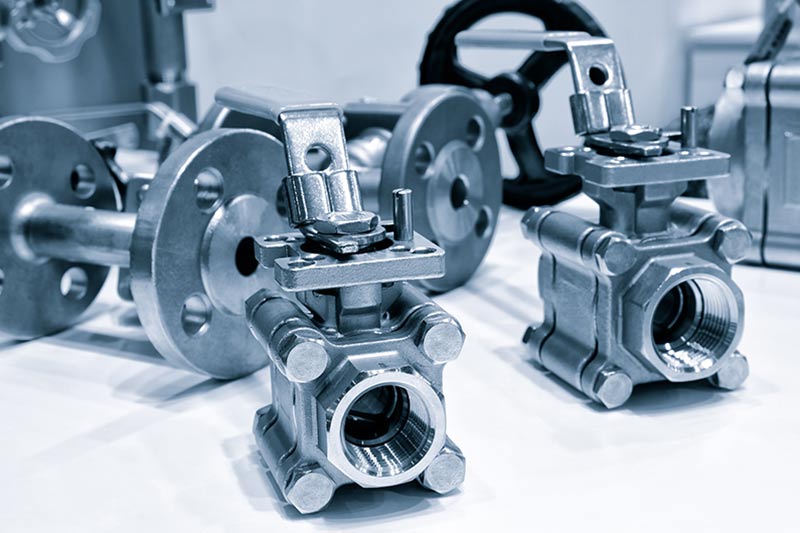

Precision-Machined Hub Assembly.

This CNC-machined hub assembly is crafted with meticulous attention to detail, ensuring stability and precision in high-performance machinery. Built to withstand rigorous conditions, it’s optimized for critical aerospace and medical applications that demand reliability.

Aerospace-Grade Structural Disk

Featuring a robust yet lightweight design, this CNC-machined disk is specifically crafted for aerospace use. The intricate structure and tight tolerances make it a reliable choice for environments where performance and safety are non-negotiable.

Medical-Grade CNC Component

This component exemplifies the precision and quality required for medical applications. With high dimensional accuracy and flawless finishing, it is crafted to meet stringent regulatory standards and ensure safety in critical medical devices.

High-Precision Surgical Component

Designed for critical medical environments, this CNC-machined component offers exceptional precision and reliability. Its high-quality finish and exacting dimensional tolerances ensure compatibility with stringent healthcare standards, making it ideal for use in life-saving surgical instruments and devices.

1-1.png)

1-2.png)

1-3.png)

1-4.png)